12× Lifespan Boost in Automotive Sandblasting

How Western Rubbers extended seal life for a U.S. automotive operation.

Proudly delivering cutting-edge inflatable rubber seals and inflatable gaskets to leading USA companies in the fastest lead time.

Proudly delivering cutting-edge inflatable rubber seals and inflatable gaskets to leading USA companies in the fastest lead time.

Why USA-Based Manufacturing Companies Choose to Work With Us?

Explore Our Resources

How Western Rubbers extended seal life for a U.S. automotive operation.

A cost-effective inflatable solution for a national space organization.

Precision end-plug sealing engineered for next-gen chip manufacturing.

A game-changing seal solution for a U.S. clean-tech company.

Eliminated leaks with FDA-grade fabric-reinforced seals.

Improved reliability for a global manufacturing leader.

Applications

Inflatable rubber seals for Robotic Automation Systems

Inflatable seals for gas-tight doors in hazardous applications

Pharmaceutical Equipment with silicone inflatable seals

Inflatable seals for airtight clean room doors

Reinforced inflatable seal solutions for Butterfly Valves

Materials That Are Suitable for Inflatable Seals

| Material | Temperature Range | Strengths | Limitations |

|---|---|---|---|

| EPDM | -50°C to 150°C | Excellent aging, ozone, weather resistance; Flexible at low temperatures | Poor resistance to petroleum oils, acids, and bases |

| Neoprene | -40°C to 125°C | Good weather and ozone resistance; Moderate oil resistance; Flame resistant | Not suitable for strong acids, esters, or gasoline |

| NBR | -40°C to 120°C | High resistance to oils and fuels; Good abrasion resistance | Poor resistance to ozone, sunlight, and weathering |

| HNBR | -40°C to 165°C | Exceptional oil/fuel resistance; Superior mechanical properties | Higher cost; Limited resistance to strong acids and bases |

| Natural Rubber (NR) | -50°C to 80°C | High resilience, flexibility; Good adhesion to metals | Poor resistance to oils, ozone, weathering; Limited temperature stability |

| Silicone (MVQ) | -60°C to 230°C | Excellent temperature resistance; Good weather and UV resistance | Poor resistance to oils, acids; Lower tensile strength |

| Fluorosilicone (FVMQ) | -60°C to 200°C | Excellent resistance to oils and solvents; Wide temperature range | Higher cost; Lower mechanical properties than silicone |

| FKM (Viton) | -20°C to 200°C | Superior chemical resistance; Excellent high-temp stability | Poor low-temperature performance; Higher cost |

Serving Unique Needs of Global Industries

Aerospace & Defence Industry

Food & Beverage Industry

Pharmaceutical & Biotechnology

Electronics & Semiconductors

Medical Devices & Healthcare

Energy & Power Industry

Cleanroom & Laboratories

Automotive & Transporation

Construction & Infrastructure

What is the ideal pressure required for operating inflatable seals?

Typically, 1-3 Bar pressure is sufficient for most inflatable seal sections. For applications requiring higher pressures, seals need to be specially designed. Western Rubbers has developed seals capable of withstanding pressures up to 30 Bar.

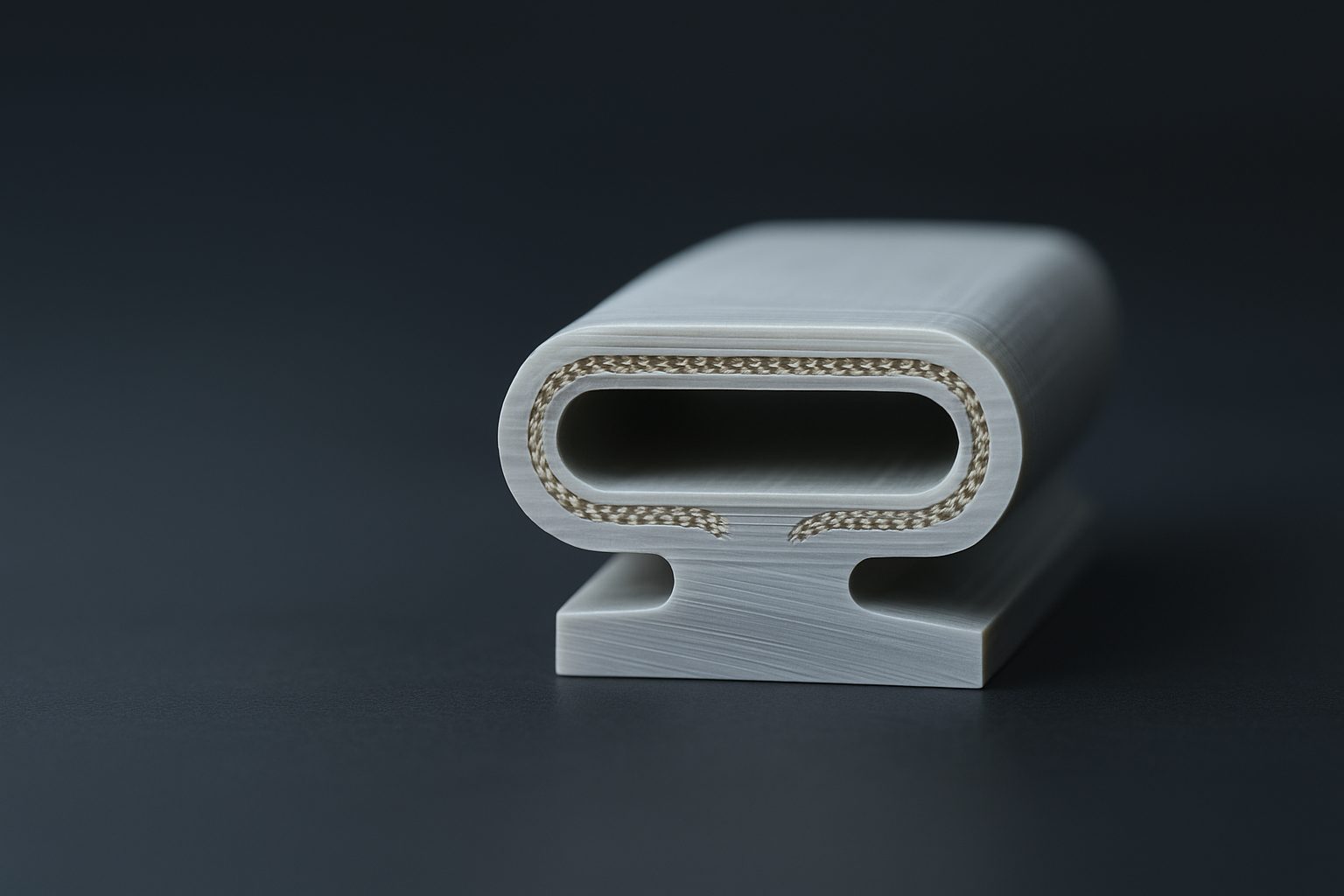

Do I need a fabric-reinforced seal?

For nominal pressure applications, non-reinforced seals are usually adequate and cost-effective. However, for pressure requirements exceeding 7-8 Bar, fabric-reinforced inflatable seals are recommended to ensure longer life and effective functionality.

What is the maximum temperature inflatable seals can withstand?

Inflatable seals can be manufactured to withstand temperatures up to 250°C (480°F).

What types of fabric reinforcement are available for inflatable seals?

Available fabric reinforcements include Kevlar, Nylon, Nomex, Polypropylene, and Dacron.

Does my inflatable seal require continuous air supply?

Inflatable seals can be designed for either continuous air supply or to function with a one-time fill, similar to a tire tube.

What should be the ideal inflation gap?

For optimal seal longevity, the inflation gap between the striking surface of the seal and the mating surface should be between 5-8 mm.

What is the maximum pressure inflatable seals can withstand?

Western Rubbers manufactures seals capable of withstanding pressures up to 30 Bar.

Do you provide design, development, and deployment services?

Yes, Western Rubbers offers comprehensive services, including design, development, and deployment, tailored to meet specific customer requirements.

Our experts are ready to provide custom solutions tailored to your project’s needs. Complete the form to start the conversation.

Western Polymer Group INC.

3524, Silverside Road, Suite 35B, Wilmington,

Delaware 19810-4929.

© 2025 Western Rubbers. All Rights Reserved.